An Industrial Computer acts as the brain of a smart factory. It collects machine data, processes information in real time, connects systems, and helps factories make quick decisions. Industrial computer manufacturers design these systems to survive tough factory conditions while supporting automation, data analytics, and smart manufacturing goals.

Manufacturing floors are no longer noisy spaces filled only with machines and workers. Today, factories think, react, and improve on their own. This change did not happen overnight. It happened because technology slowly entered every corner of production.

From small assembly lines to large automated plants, industrial computers quietly manage data, machines, and decisions. They help factories work faster, reduce errors, and stay ready for the future.

In this blog, you will understand how industrial computer manufacturer support industry 4.0, why smart factories depend on them, and how companies like Global Infotech Solutions help Indian industries move forward with confidence.

Understanding Industry 4.0 in Simple Words

Industry 4.0 means using digital systems to make factories smarter. Machines talk to machines. Data flows automatically. Decisions happen faster.

Instead of manual checks and paper reports, factories now depend on real-time data.

Key elements of Industry 4.0 include:

- Connected machines

- Real-time monitoring

- Automation systems

- Data-driven decisions

- Predictive maintenance

All these elements depend heavily on industry 4.0 computer solutions that can work without failure.

Why Industrial Computers Matter More Than Regular PCs

A home or office computer cannot survive factory conditions. Heat, dust, vibration, and continuous use can break normal systems.

An Industrial Computer is built differently.

Difference Between Industrial Computer and Regular Computer

| Feature | Industrial Computer | Regular Computer |

|---|---|---|

| Operating hours | 24 by 7 | Limited |

| Heat resistance | High | Low |

| Dust protection | Industrial-grade | Minimal |

| Lifespan | Long-term use | Short |

| Stability | Very high | Medium |

This is why reliable industrial computers for factories are essential for modern production environments.

How Industrial Computer Manufacturers Support Industry 4.0

Industrial computer manufacturers do more than sell hardware. They design solutions that fit real factory needs.

Let us break this down clearly.

1. Supporting Smart Factory Automation

Smart factories rely on automated systems that run without constant human input.

An industrial pc for automation controls:

- Conveyor belts

- Robotic arms

- Packaging systems

- Quality inspection machines

These computers process commands instantly and reduce delays.

Benefits of Automation with Industrial Computers

- Faster production cycles

- Fewer human errors

- Stable operations

- Lower downtime

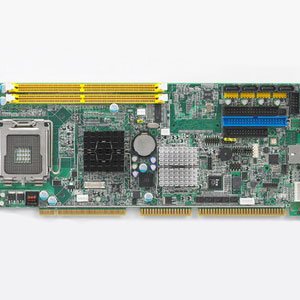

Manufacturers design these systems to work with PLCs, SCADA, and MES platforms.

2. Enabling Real-Time Data Monitoring

Data is the backbone of smart factories.

Industrial computers collect data from:

- Sensors

- Machines

- Production lines

- Energy systems

This data helps managers track performance instantly.

What real-time monitoring helps with

- Detecting machine issues early

- Improving output quality

- Reducing energy waste

- Tracking production targets

Industry 4.0 computer solutions focus heavily on real-time data handling.

3. Edge Computing for Faster Decisions

Cloud systems are useful, but factories cannot always wait for cloud responses.

This is where an industrial edge computer manufacturer plays a vital role.

Edge computers process data near the machine itself.

Why edge computing matters in factories

- Faster response time

- Less internet dependency

- Better data security

- Stable operations during network issues

Industrial computer manufacturers build edge systems that fit directly inside factory panels or machines.

4. Supporting Predictive Maintenance

Breakdowns cost time and money.

Industrial computers analyze machine behavior and alert teams before failure happens.

Predictive maintenance helps factories

- Plan repairs early

- Avoid sudden shutdowns

- Extend machine life

- Reduce maintenance costs

This feature plays a big role in smart factory computer solutions.

5. Seamless System Integration

Factories use many systems together.

Industrial computers connect:

- ERP systems

- MES platforms

- PLC controllers

- IoT devices

This smooth connection helps all systems work as one unit.

Integration advantages

- Unified data flow

- Better planning

- Faster reporting

- Clear decision-making

Industrial computer manufacturers ensure compatibility with popular industrial protocols.

Role of Global Infotech Solutions in Smart Manufacturing

Global Infotech Solutions focuses on delivering stable, long-term industrial computing systems for Indian industries.

They understand factory challenges and offer systems built for Indian operating conditions.

What makes Global Infotech Solutions reliable

- Industrial-grade hardware

- Custom configuration support

- Local technical understanding

- Industry-focused designs

Their approach matches real factory needs rather than generic computing demands.

Common Types of Industrial Computers Used in Smart Factories

| Type | Usage |

|---|---|

| Panel PCs | Machine interface and control |

| Embedded PCs | Inside machines |

| Industrial Box PCs | Control rooms |

| Edge Computers | Data processing near machines |

| Rackmount Systems | Large-scale operations |

Each type supports specific factory tasks.

How Industrial Computer Manufacturers Improve Factory Safety

Safety remains a top concern.

Industrial computers help by:

- Monitoring unsafe conditions

- Triggering alerts

- Stopping machines automatically

- Tracking safety compliance

This makes factories safer without slowing production.

Challenges Faced Without Industrial Computers

Factories that avoid upgrading face many issues.

Common problems

- Frequent breakdowns

- Manual monitoring

- Delayed decisions

- High maintenance costs

- Poor data visibility

Modern manufacturing cannot survive without digital support.

Mistakes Factories Make While Choosing Industrial Computers

Many factories struggle due to poor selection.

Avoid these common mistakes

- Choosing office PCs for factory use

- Ignoring future scalability

- Overlooking heat and dust resistance

- Skipping local technical support

- Focusing only on price

Experienced Industrial Computer Manufacturers help avoid these errors.

Why India’s Manufacturing Sector Needs Industrial Computers

India is moving fast towards smart manufacturing.

Government programmes, export demands, and quality standards push factories to modernise.

Benefits for Indian factories

- Global competitiveness

- Improved production quality

- Reduced labor dependency

- Better energy usage

Industry 4.0 computer solutions play a big role in this growth.

Future Trends in Industrial Computing

Industrial computing continues to evolve.

Upcoming trends

- AI-ready industrial computers

- Compact edge systems

- Higher cybersecurity standards

- Energy-efficient designs

- Remote monitoring support

Industrial computer manufacturers continuously update designs to match future needs.

How to Choose the Right Industrial Computer Manufacturer

Before selecting a supplier, factories should consider:

Selection checklist

- Experience in industrial environments

- Customization options

- After-sales support

- Long product lifecycle

- Compatibility with automation systems

Global Infotech Solutions aligns well with these requirements.

Conclusion

Industry 4.0 and smart factories rely on systems that can work continuously, handle real-time data, and support automation without failure. The industrial computer makes this possible by acting as the control and processing layer inside modern factories. By designing durable, factory-ready systems, industrial computer manufacturers help industries adopt industry 4.0 computer solutions that improve efficiency, visibility, and reliability. With the right industrial computing support from partners like Global Infotech Solutions, manufacturers can move toward smarter operations with confidence and long-term stability.

FAQ

1. How does an Industrial Computer differ from automation controllers like PLCs?

An Industrial Computer handles data processing, monitoring, visualization, and system integration, while PLCs focus mainly on machine-level control. Both work together in smart factories but serve different purposes.

2. Can industrial computers run continuously without shutdowns?

Yes. Industrial computers are designed for 24 by 7 operation. They use industrial-grade components that support continuous workloads without performance drops.

3. Do smart factories always need cloud connectivity?

No. Many smart factories use edge computing. Industrial computers process data locally to ensure faster response and stable operations even when internet connectivity is limited.